Print the plastic parts

Tools

- 1 Precision wire cutter

- 1 RepRap-style printer

- 1 Utility knife - Not a scalpel!

Materials

- 50 g of Black PLA filament

- 205 g of PLA filament - Of any colour you want

Step 1: Set your printer settings

Almost all station parts can be printed out of PLA filament on most RepRap-style printers.

We recommend the following printer settings:

| Setting | Value |

|---|---|

| Material | PLA |

| Material Temperature | Recommended by the PLA brand |

| Layer height | 0.2mm or less |

| Infill | Printer default |

| Brim | Recommended for all parts |

| Slice gap closing radius | 0.001mm |

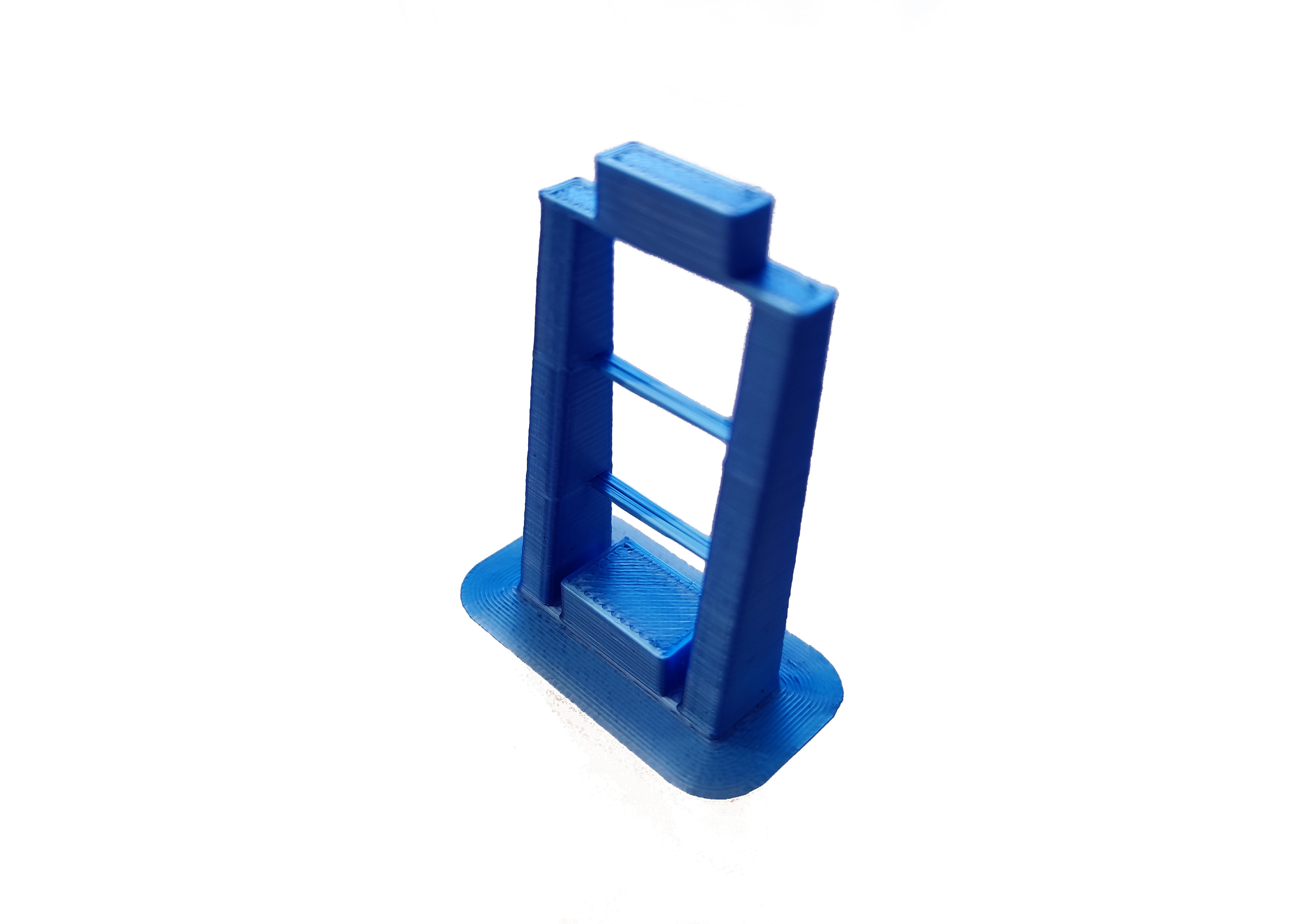

Test whether your printer can print the pieces for this station or other open-source designs. Download and print the leg test file. This will only use about 5 grams of PLA.

The result should look like this (this has been printed with a brim):

As a general rule, strength is more important than surface finish, so very thin layers (less than 0.15mm or so) are unlikely to result in a station that performs any better, though it may approve the appearance.

Step 2: Printing

Now you have tested your 3D printer and filament you can print the following parts:

- Actuator assembly tools (nut tool, band tool, and band tool cover): actuator_assembly_tools.stl

- Focusing assembly: focusing-assembly.stl

- Actuator Foot: z_foot.stl

- Thumbwheel: thumbwheel.stl

- Pi camera platform: camera-platform.stl

- Lens spacer: lens-spacer.stl - This must be printed in black!

- Illumination base: illumination-base.stl - This must be printed with supports

- Illumination slider: illumination-slider.stl

- Illumination thumbscrew: illumination-thumbscrew.stl

- Illumination arm: led-arm.stl - This must be printed with supports

- Hinge pin: arm-pin.stl

- LED cover: led-cover.stl

- Standoff-S: standoff-S.stl

- Standoff-M: standoff-M.stl

- Foot-M: foot-M.stl

- Spacer-S: spacer-4mm.stl

- Spacer-M: spacer-11mm.stl

For the printing do not use less than 15% infill.

You can download all the STLs as a single zipfile (plates are not included).

Step 3: Clean-up of printed parts

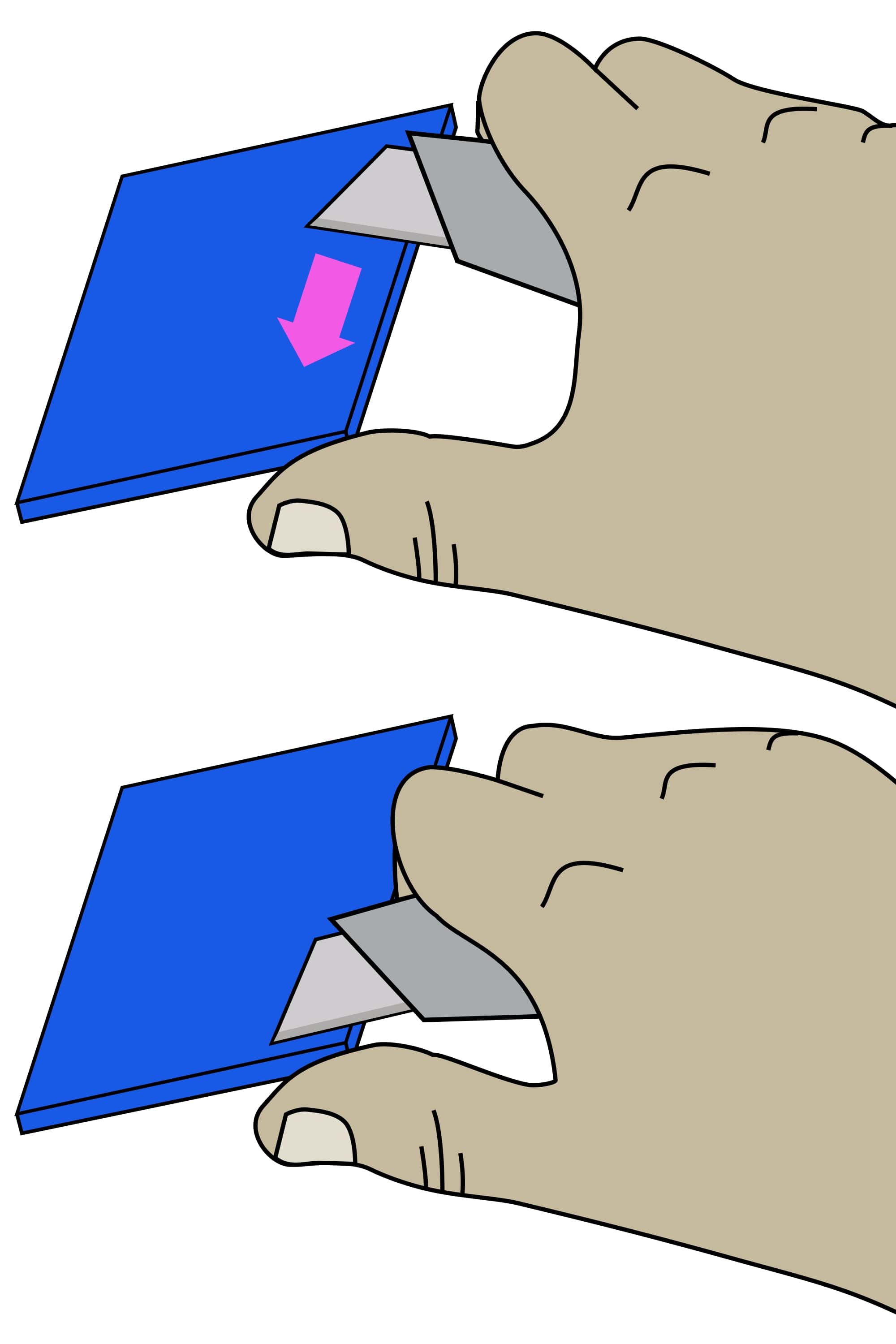

Be careful when removing brim

To avoid injury, first remove the bulk of the brim without a knife. Remove the remaining brim with a peeling action as described below.

Carefully remove the printing brim from all parts. To remove brim:

- Use precision wire cutters to remove most of the brim from the part.

- Clean up the remaining brim with a utility knife:

- Hold the knife in your dominant hand with 4 fingers curled around the handle, leaving your thumb free.

- Hold the part in your other hand, as far away from the surface, to be cut as possible.

- Support the part with the thumb of your dominant hand.

- Place the blade on the surface to be cut, and carefully close your dominant hand, moving the blade, under control, towards your thumb.